Back then, China stood at the lower end of the global industrial value chain, producing mostly cheap and technically backward products. Made in China 2025 sought to change that, allowing Chinese manufacturing, through scientific and technological advancements, to produce high-quality, hi-tech and high-value products.

But based on official books published a decade ago and other authoritative sources, the Post has compiled more than 260 goals previously proposed under the plan. These goals span 10 key areas, many involving highly specialised and complex technologies.

Some goals remain unfulfilled, including advanced photolithography technology which is used in circuit manufacturing, intercontinental passenger aircraft and broadband internet satellite networks. This year, the Chinese government has proposed another ambitious plan to develop “new productive forces”, which is seen as a continuation of the Made in China 2025 initiative.

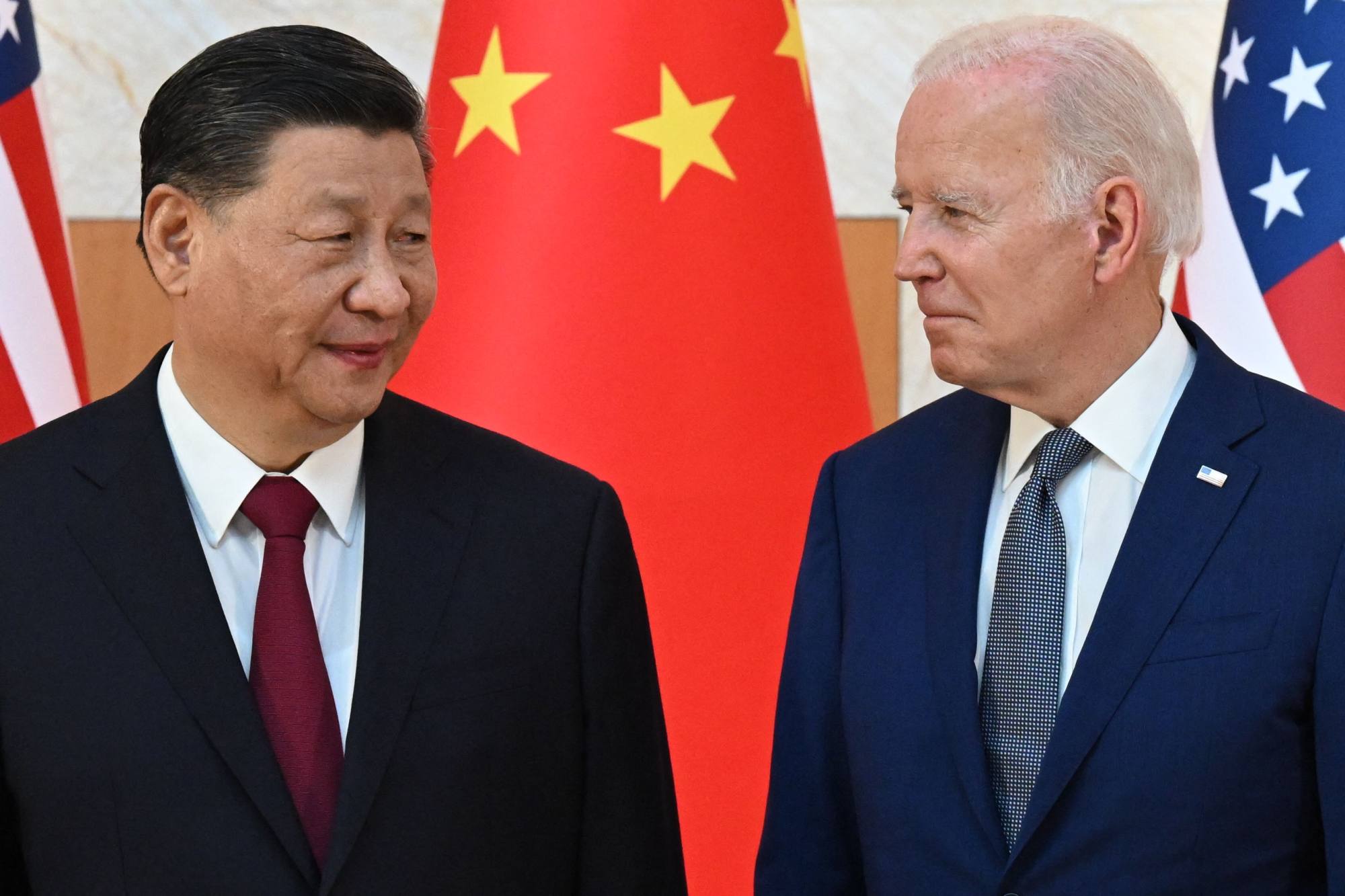

But it is doubtful just how successful they may be. Looking at the restrictive measures the West has put in place to date, they have proven limited in their effectiveness – and sometimes even counterproductive.

One of the areas where China has faced the most roadblocks has been the information technology industry.

Despite this challenge, China has achieved most of the goals set in integrated circuits, communication equipment, operating systems, industrial software and smart manufacturing. Chinese companies can now produce high-value products including servers, desktop CPUs, solid-state drives, high-speed fibre optics, industrial operating systems and big data systems. Some of these products have captured a considerable market share.

In the field of photolithography technology, Huawei Technologies has achieved double or multiple exposure processes for high-end chip manufacturing. However, China has not yet achieved industrialisation of the most advanced EUV photolithography technology, so this goal has not been fully achieved.

The goal of autonomous measuring and detection equipment has also not been accomplished, in part because there are fewer US sanctions in this field. According to the latest industry data, most smart meters and online compositional analysis equipment used in the Chinese market are still foreign brands.

In the world of EVs, the technologically advanced vehicles produced in China have been eagerly sought by global consumers, propelling China to surpass Japan as the world’s biggest car exporter last year.

In fact, the more acclaim the Chinese EVs attract, the more sanctions they are hit with; they have become the main target of a new round of sanctions and tariffs with the US and some European countries citing Chinese government intervention as their reasons for the move.

Chinese electric vehicles are not only price-competitive but also technologically ahead of their competitors. As early as a decade ago, the Chinese government set the development of low-cost, high-performance, vehicle-mounted lidar as a national goal. This has enabled Chinese carmakers to develop more reliable and powerful intelligent driving systems than competitors like Tesla, which do not use lidar.

Nowadays, new Chinese-branded cars can connect to the internet and provide rich entertainment features – something which was also planned a decade ago.

Aerospace is one of the longest-sanctioned sectors in China. Chinese satellites and rockets cannot use American chips, components or technology. Non-Western satellites using US technology cannot be launched in China. Nasa scientists are also banned by law from any communication with their Chinese counterparts.

The strict rules meant Chinese scientists and engineers had to rely purely on their own efforts – and it has paid off. They have achieved almost all the goals, including Mars landing exploration, the global BeiDou satellite navigation system, a space station, landing on the far side of the moon and building the world’s largest commercial satellite observation network for Earth observation.

However, the speed of building a giant internet satellite constellation to compete with Starlink has been slower than expected. Also, the asteroid exploration plan originally scheduled for launch in 2023 has been postponed to 2025.

Meanwhile, in China’s power equipment technology sector, according to the Post’s investigation, the Made in China 2025 plan has seen the country transform from a follower to a leader.

They have also created the world’s most powerful hydroelectric generating units, the most efficient solar power stations, the most powerful wind turbines and the most advanced, largest-scale long-distance transmission and distribution network.

These advances have had a ripple effect, improving the global competitiveness of China’s entire manufacturing sector, and also potentially impacting future artificial intelligence (AI) competition because of AI’s high energy consumption.

The sector’s unmet goals include ultra-high-power gas turbine power generation equipment and a 2 gigawatt nuclear pressurised water reactor.

Chinese companies can independently design and manufacture the world’s most advanced superconducting magnetic resonance system, which can generate a magnetic field of 5 tesla, 70 per cent higher than the planned target. Its price is just one-tenth of similar Western products, significantly reducing the cost of hospital examinations for Chinese patients needing MRIs.

Anti-cancer drugs developed by Chinese companies have started to enter the US market, with prices just a fraction of similar drugs offered by Western pharmaceutical companies.

Technological advancements have also significantly increased China’s agricultural output. Despite limited cultivated land, China produces more than half the world’s vegetables, thanks to the use of drones, automatic seeders and biotechnology.

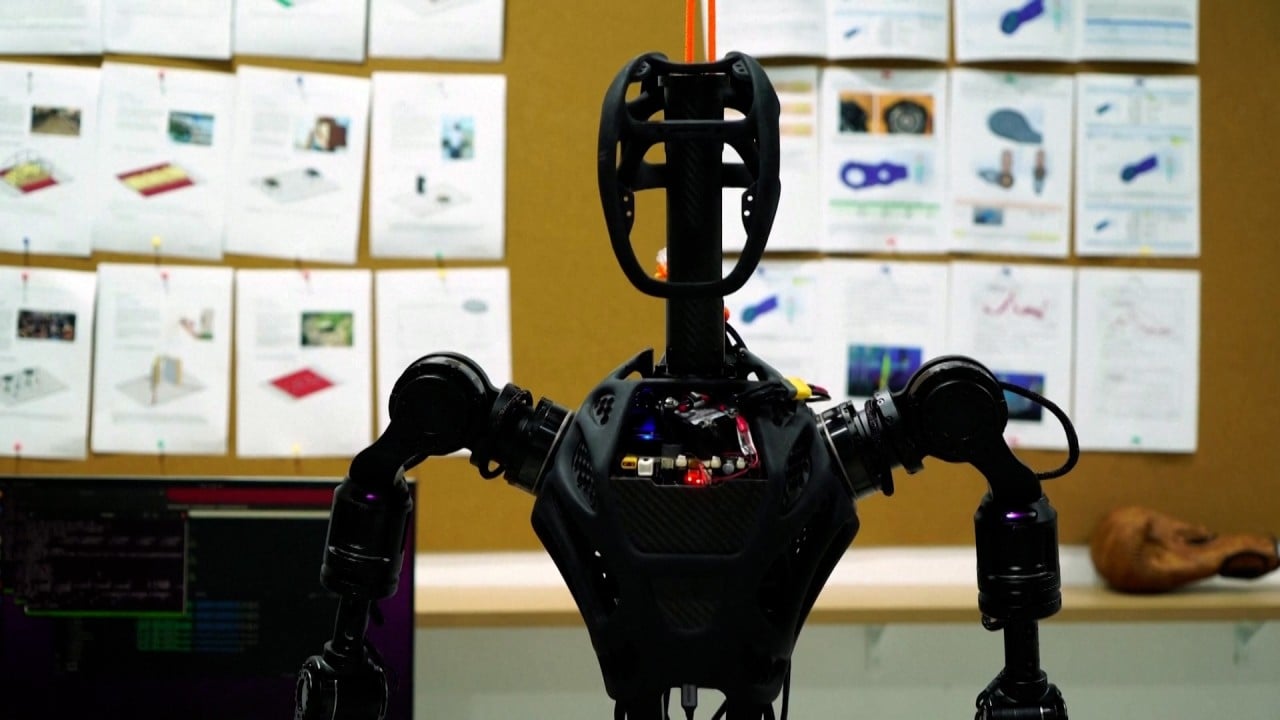

Products like robot dogs made by Chinese companies have also beaten international competitors with leading performance and low prices.

The sector with the lowest Made in China 2025 completion rate is new materials, now at only 75 per cent.

The pending targets include the industrialisation of large-size deep-ultraviolet non-linear crystals, low-cost titanium alloy powder, certain special superconducting materials, graphene electrode materials that can double the range of lithium-ion battery-powered cars, and some special chemical materials.

“China has basically achieved the vision set 10 years ago,” according to Zang Jiyuan, a scholar specialising in strategic research on China’s manufacturing sector at the Chinese Academy of Engineering (CAE).

“Manufacturing development in China has never been at a standstill, and containment by the West has been accelerating China’s efforts to achieve technological self-reliance.”

Many other countries have initiated similar plans to bolster their manufacturing sector. Germany’s “Industry 4.0”, introduced in April 2013, focused on digitising supply, manufacturing and sales data within production processes. The US launched the “Industrial Internet Revolution” at about the same time, aiming to improve industrial processes through the Internet of Things and big data technologies.

In May 2015, Japan’s Ministry of Economy, Trade and Industry initiated a plan for a digital upgrade of the manufacturing sector. France also launched its “New Industrial France” programme to adapt digitisation and smart technologies.

Since 2012, a team led by CAE researchers has been working on a scoring system to measure the performance and strength of the manufacturing sector in nine major countries. The results show that China has made significant progress over the past decade.

While total output is important, the index also measures dimensions such as the economic efficiency, innovation and industrial structure of the manufacturing sector. For example, if a country’s manufacturing sector has more globally recognised brands, higher R&D investment intensity and higher product profitability, it will receive a higher score in the system.

In 2012, China scored 89 points, placing it fourth in the world, with the United States (156), Japan (126) and Germany (119) making up the top three.

By comparison, according to the latest annual report released at the end of December last year, China was still in fourth place in 2022, but the gap between its scores and those of the other three countries had narrowed, with the United States, Germany, Japan and China scoring 182, 133, 126 and 124 respectively.

Going by this index alone, Germany and Japan have maintained a relatively stable pace, while the US is making rapid progress and is well ahead of other countries.

“The US is still the undisputed world leader in manufacturing, especially in industries such as military technology and aerospace,” Zang said.